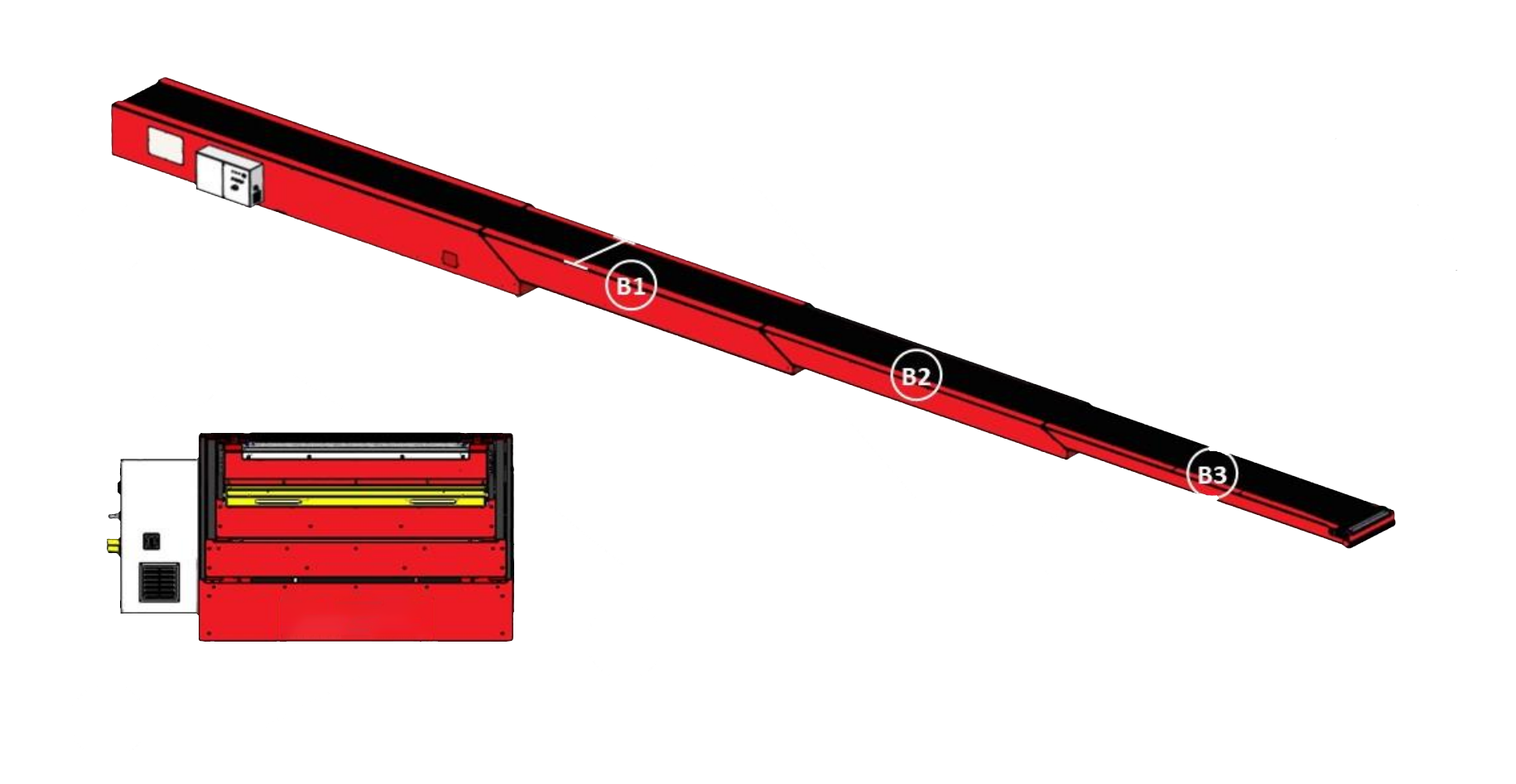

| Model No | *L (mm) | *M (mm) | *E (mm) | B | B1 | **C | H (mm) | W |

|---|---|---|---|---|---|---|---|---|

| Total Length | Main Base Length | Extension | Booms | Boom #1 Width | Conveying Width | Main Base Height | Main Base Width | |

| B-TLS 2,5/1/1/3,5 | 3.500 | 2.500 | 1.000 | 1 | C + 286 | 600/800/1000 | 550 | C + 350 |

| B-TLS 5/2/7/12 | 12.000 | 5.000 | 7.000 | 2 | C + 340 | 600/800/1000 | 600 | C + 396 |

| B-TLS 5/3/10/15 | 15.000 | 5.000 | 10.000 | 3 | C + 394 | 600/800/1000 | 750 | C + 450 |

| B-TLS 5/4/14/19 | 19.000 | 5.000 | 14.000 | 4 | C + 390 | 600/800/1000 | 990 | C + 505 |

| B-TLS 6/2/9/15 | 15.000 | 6.000 | 9.000 | 2 | C + 340 | 600/800/1000 | 600 | C + 396 |

| B-TLS 6/3/13/19 | 19.000 | 6.000 | 13.000 | 3 | C + 394 | 600/800/1000 | 750 | C + 450 |

| B-TLS 6/4/16/22 | 22.000 | 6.000 | 16.000 | 4 | C + 450 | 600/800/1000 | 990 | C + 505 |

| B-TLS 7,5/3/15/22,5 | 23.000 | 7.500 | 15.000 | 3 | C + 394 | 600/800/1000 | 820 | C + 450 |

| B-TLS 7,5/4/20/27,5 | 27.000 | 7.500 | 20.000 | 4 | C + 450 | 600/800/1000 | 990 | C + 505 |

| B-TLS 9,2/3/19,8/29 | 29.000 | 9.200 | 19.800 | 3 | C + 394 | 600/800/1000 | 820 | C + 450 |

| B-TLS 5.5/1/3.5/9 Bended | 9.000 | 5.500 | 3.500 | 1 | C + 286 | 600/800/1000 | 600 | C + 396 |

| B-TLS 5.5/2/7/12.5 Bended | 12.500 | 5.500 | 7.000 | 2 | C + 340 | 600/800/1000 | 780 | C + 396 |

| B-TLS 7.5/3/16.5/24 Bended | 24.000 | 7.500 | 16.500 | 3 | C + 394 | 600/800/1000 | 950 | C + 450 |

B-TLS 4/3/7,5/11,5

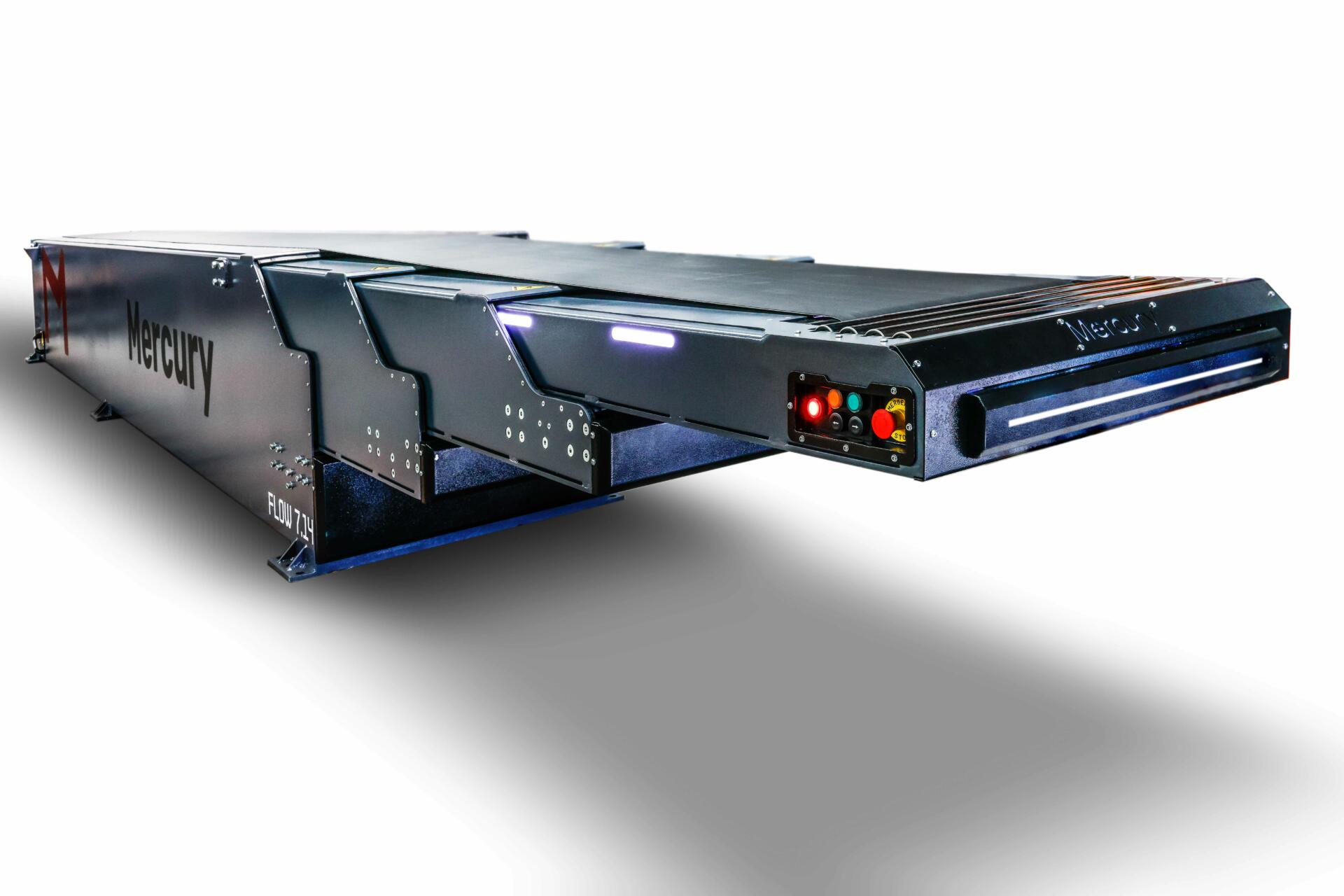

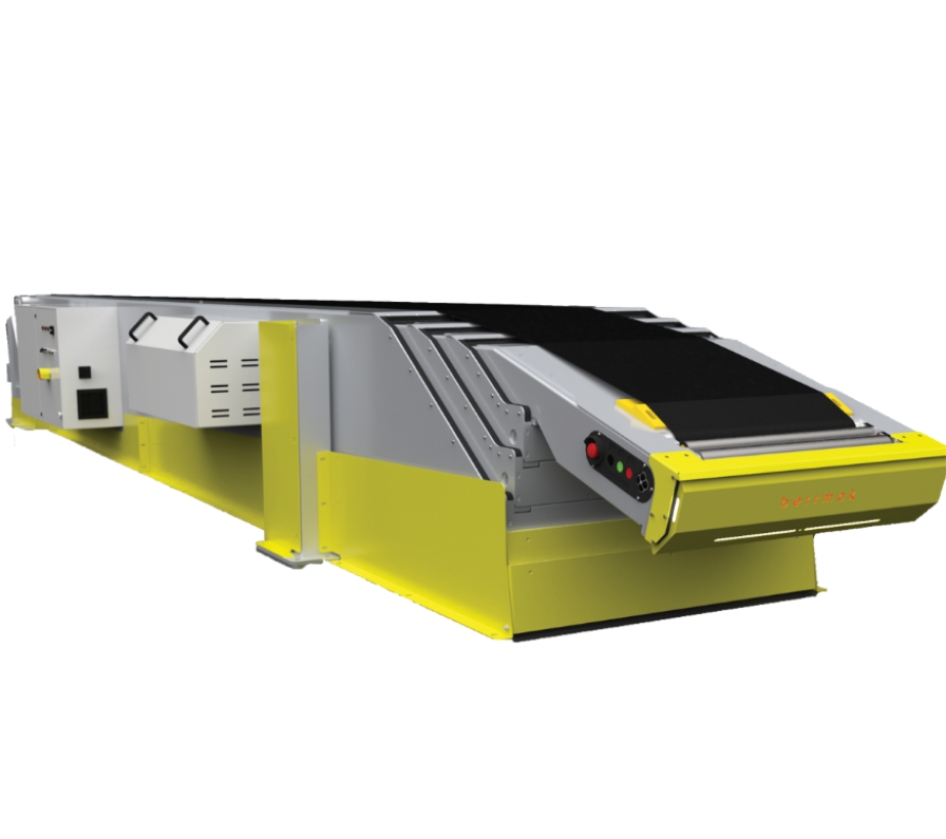

Robust telescopic conveyor for safe and efficient loose loading & unloading.

This market-leading telescopic conveyor offers seamless transport for various loads in warehouse & distribution material handling operations where operations need to move rapidly and efficiently.

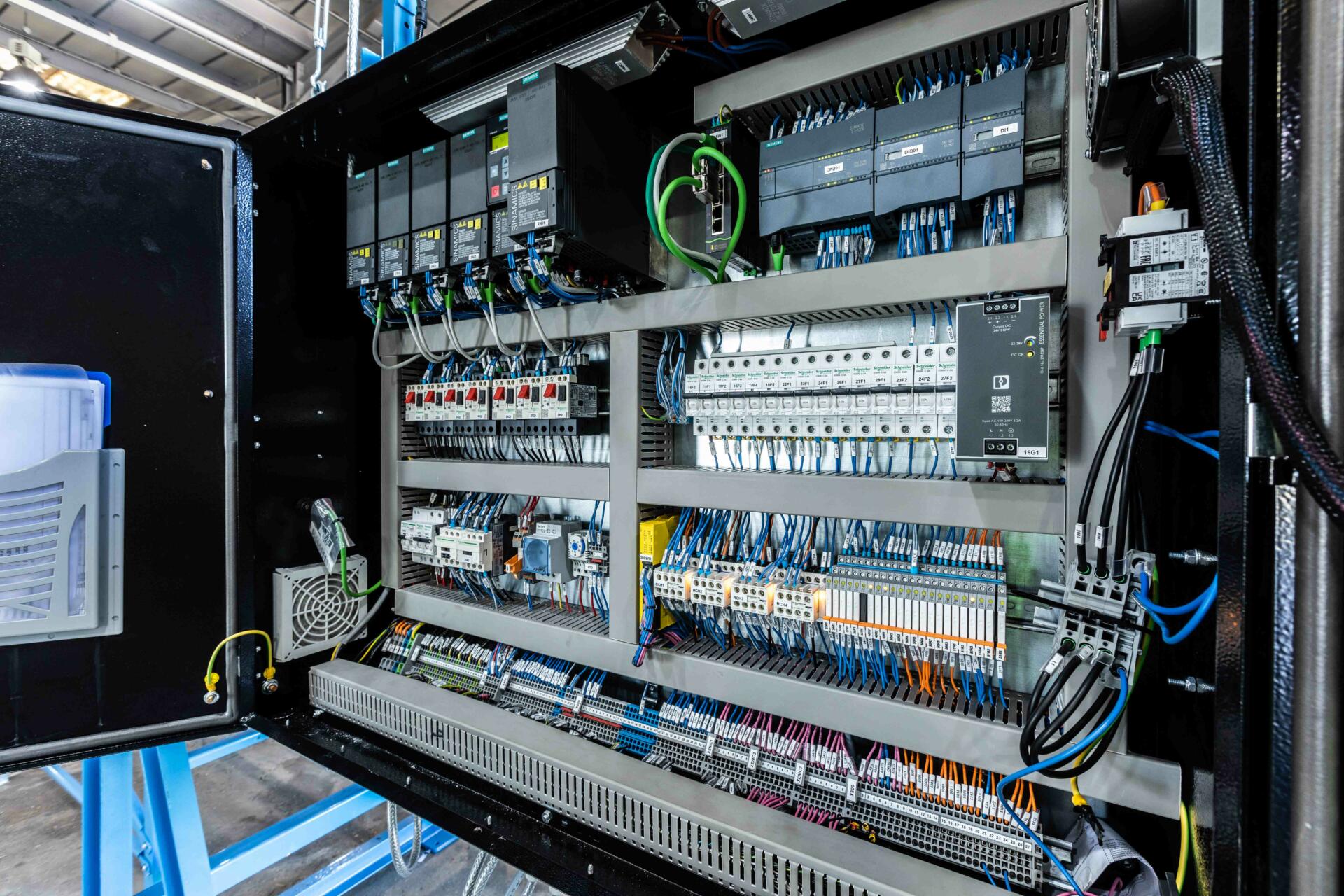

Built to last, this conveyor features a 10mm thick main casing with a high-end parts specification made up of parts from leading manufacturers such as SICK, Siemens, Interroll and SEW. Versatile in design, extending sections penetrate the trailer or van which enables operators to move goods quickly and safely.

Specifications

| Mains Supply | 400 ACV, 3ph+PE+N, 50Hz, 16 A |

| Transport Speed | 0,25 – 0,55 m / sec (Adjustable speed) |

| Extend Speed | 0,20 – 0,30 m / sec |

| Load Capacity | 50 kg / m |

| Emergency Stop | Both sides of the front boom and one on the control cabinet |

| Control Buttons | Both front sides of the front boom |

| Safety Crash Bar | 2 Way anti-collision protection on the tip of front boom |

| Control Cabinet position | Left / Right (Looking from the rear of the machine) |

| Safety pop-out roller | On Loading Units |

| Belt Drive | Drum Motor |

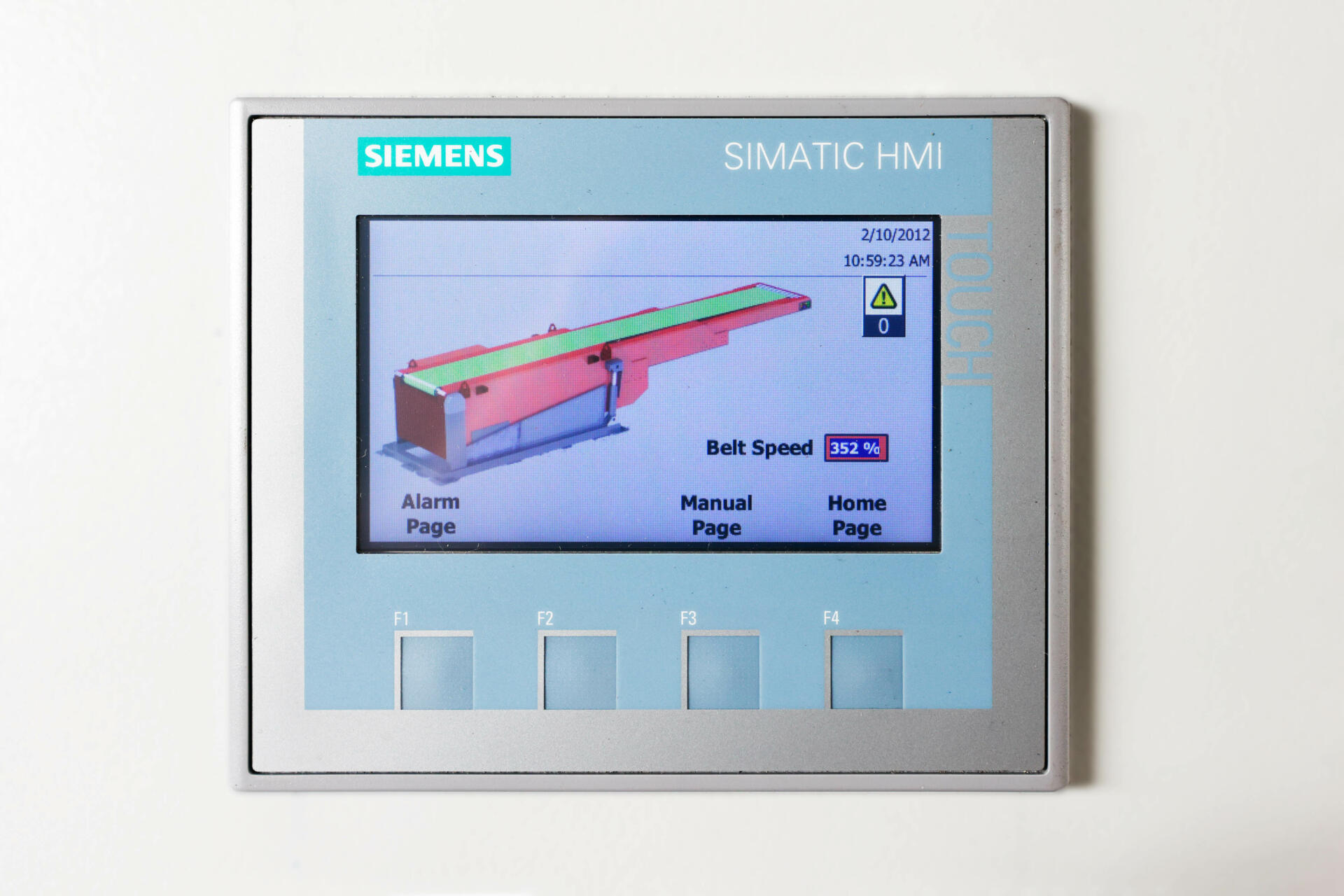

| PLC | Siemens S7 1214 |

| Communication interface | Via hardwired 24VDC Signals |

| EMS Interface | Via Safety Relay 24VDC Signals |

Standard Features

Fitted with powerful, high-spec features to streamline all of your handling operations, this multi-functional telescopic conveyor can facilitate almost any conceivable unloading & offloading operation.

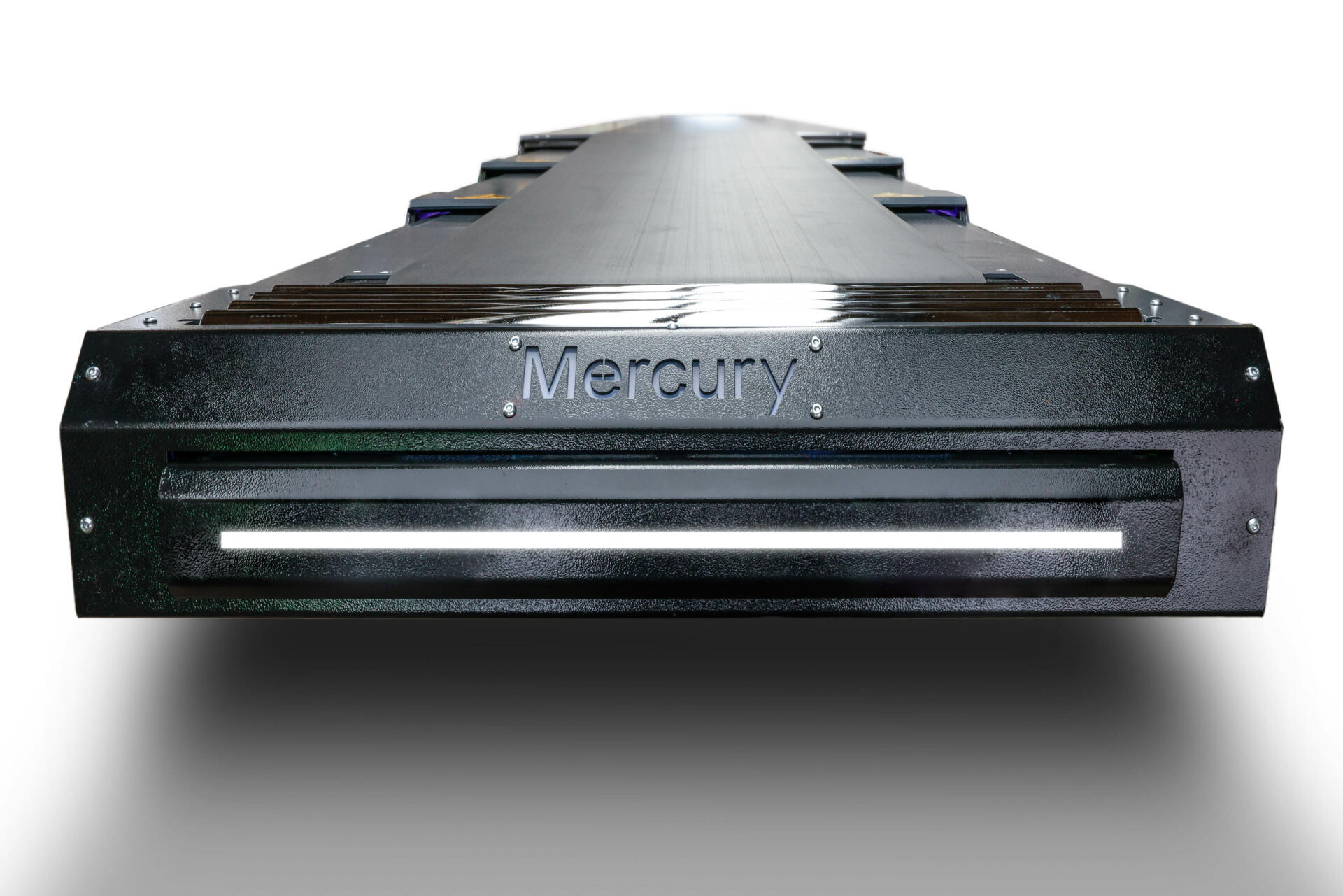

- End Lights

End Lights

Full visibility, LED lights are fitted at the front end and alongside both sides of the front boom to light up the operators’ location.

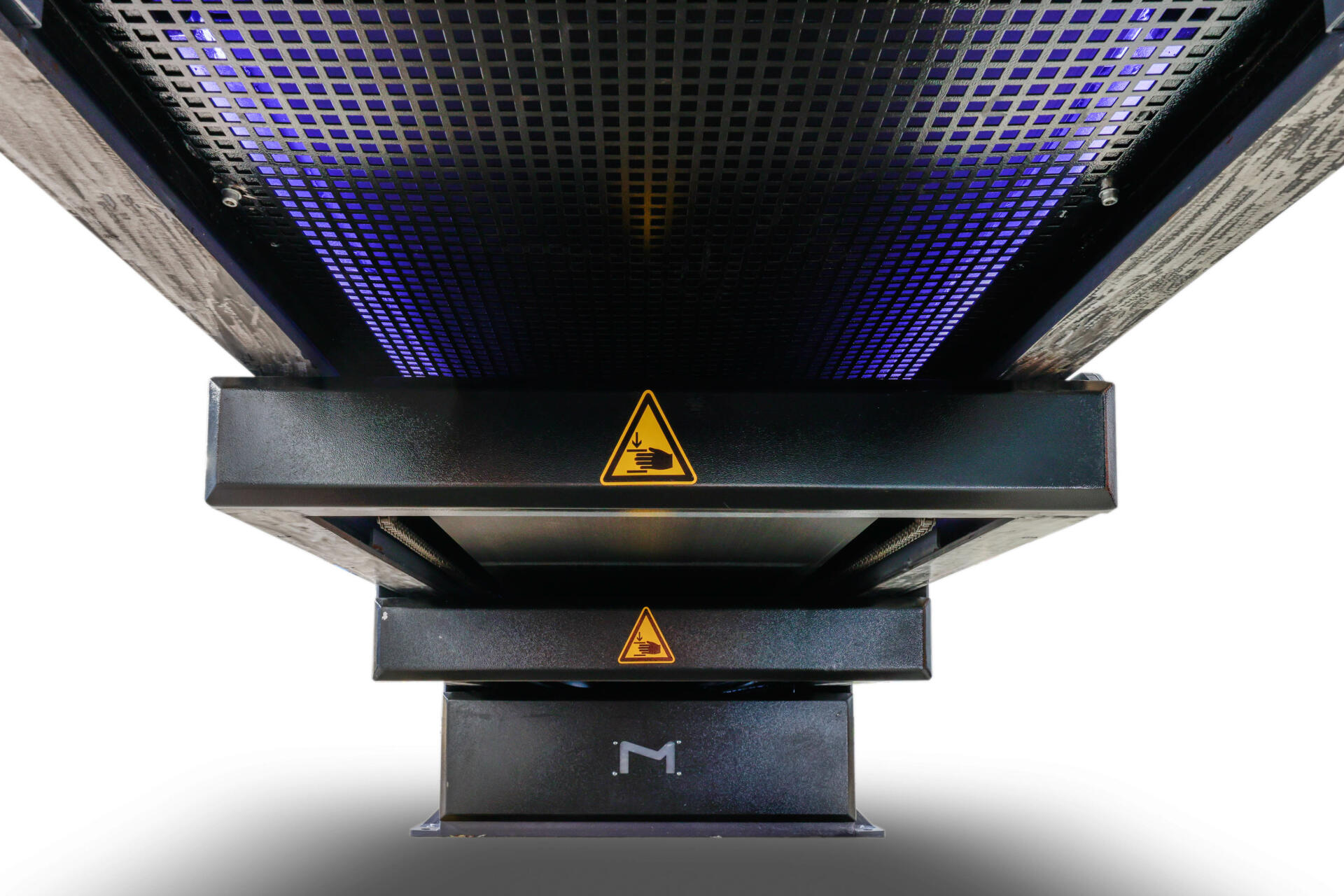

- Safety Crash bar

Safety Crash bar

Designed to prevent collisions, a safety crash bar fitted at the front of the conveyor stops it from extending immediately when activated.

- Soft start

Soft start

Ensuring smooth and seamless operations, soft start allows for a gradual speed increase when both the belt is started or the boom in / out buttons are activated.

- Emergency Stop Shrouds

Emergency Stop Shrouds

Emergency stop damage is reduced with the inclusion of steel shrouds.

- Underside covers

Underside covers

Covers are included throughout the length of the conveyor to eliminate unauthorised interior access.

- Front Control Panel

Front Control Panel

An easy-to-use control panel on both sides of the conveyor includes emergency stops, belt run, and boom in and out.

- HMI Screen

HMI Screen

Allows authorised personnel to quickly and easily perform and adjust control functions.

Optional Extras

Through our bespoke service and a range of sizes and accessories available, Mercury Conveyors can tailor a solution to meet your specific requirements to make sure you’re getting the most out of your conveyor.

- Reversible belt

Reversible belt

The conveyor can run multi-directional with the reversible belt option. This also includes an unload/load switch and belt-tracking device monitors for full control. Feed and run buttons are positioned at the front of the conveyor.

- Belt stop sensor

Belt stop sensor

Enable greater control and prevent goods from falling off at the front end with the addition of a feed sensor at the front of the loader.

- Bended Front Boom

Bended Front Boom

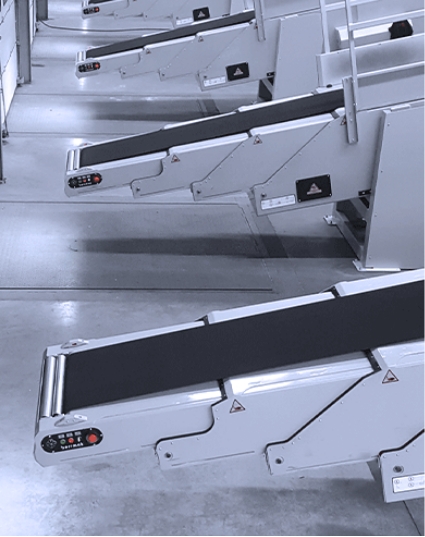

When vehicles of varying heights are to be loaded at the same loading bay, a bended front boom can be raised and lowered accordingly.

- Hydraulic Tilt

Hydraulic Tilt

Easily adjust the height of the conveyor with the addition of a hydraulic ram at the front of the main casing.

- Side Guides

Side Guides

This accessory keeps goods on the conveyor and prevents them from falling off the side. This option is particularly beneficial when installed on high level telescopic conveyors.

- High Supports

High Supports

When loading from the floor, high supports raise the loader to the required height.

- Flow Control Sensor

Flow Control Sensor

Easily manage the flow of your goods with a flow control sensor which is located at the rear of the conveyor and communicates with the main line.

- Bended Boom

Bended Boom

When you’re working with different types of vehicles, the bended boom offers flexibility to interchange between vans and trailers.

- Operator Platform

Operator Platform

Enable a comfortable ergonomic height for your operators when loading and unloading. This platform can be raised and lowered with the conveyor, which is particularly beneficial when handling goods at the top of the vehicle.

Increase productivity and profitability with automated fulfilment solutions.

Telescopic conveyors quickly become a cost-saving investment for your business. Automated fulfilment operations provide greater accuracy and productivity with faster loading and unloading times, meaning that you can ship your goods quicker and benefit from increased turnover.

This safe and efficient operation protects against product damage, ensuring all goods are handled carefully which minimises any loss in profits due to mishandling.

Reduce the number of operators needed in your material handling operations.

High-pressure distribution environments need highly efficient processes, and that’s exactly what our telescopic conveyors bring to the table. This automated solution allows you to reduce the need for manual labour, decreasing your salary output and minimising the risk of workplace injuries.

Let your workforce put their skills into the tasks that need them the most, and let our robust and reliable telescopic conveyors do the hard work.